Hinged Expansion Bellows

80000.0 INR/Unit

Product Details:

- Media Air, SO2, Steam, Water, Oil, Acid, Gas

- Head Code Square

- Surface Treatment Painted, Polish

- Usage To compensate the movements occurs during thermal and movement

- Material Iron, Stainless Steel, Titanium, Alloy, Carbon Steel

- Technique Others

- Type Flange

- Click to View more

X

Hinged Expansion Bellows Price And Quantity

- 80000.0 INR/Unit

- 1 Number

Hinged Expansion Bellows Product Specifications

- To compensate the movements occurs during thermal and movement

- hinged bellow

- Air, SO2, Steam, Water, Oil, Acid, Gas

- Flange

- Iron, Stainless Steel, Titanium, Alloy, Carbon Steel

- Painted, Polish

- Square

- Flange, Welding

- Equal

- upon Request

- Others

Hinged Expansion Bellows Trade Information

- Cash in Advance (CID)

- 100 Number Per Month

- 1 Week

- Contact us for information regarding our sample policy

- All India

Product Description

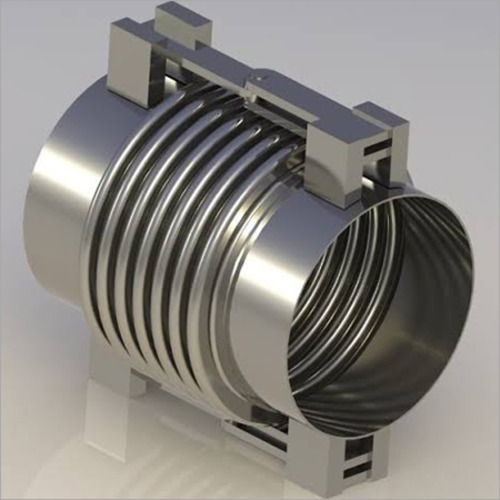

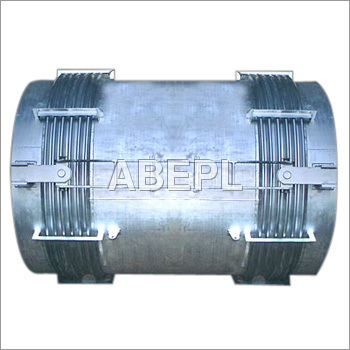

Hinged Expansion Bellows (or Hinged Expansion Joints) are designed to allow angular movement in a single plane while restricting axial or lateral movement. Heres what they typically contain or consist of:

Main Components of Hinged Expansion Bellows:

Bellows Element:

- The flexible core that accommodates movement.

- Made from stainless steel (e.g., SS 304, SS 316L, Inconel).

Hinges (Hinge Assemblies):

- Two hinge plates (arms) connected with a pin.

- Allow angular movement in one plane only.

- Restrict axial and lateral movements.

- Often made from carbon steel or stainless steel.

End Connections:

- Weld ends, flanges, or threaded ends.

- Connect the bellow to the pipeline or equipment.

Gussets / Lugs (part of hinge assembly):

- Provide support for hinge arms and distribute loads.

Stops or Limit Devices (optional):

- To control the maximum angular movement.

- May include pins, blocks, or tie rods depending on design.

Functional Purpose:

- Allows angular deflection only (not axial or lateral).

- Typically used in pairs or sets of three to absorb thermal expansion in piping systems by redirecting the movement.

- The hinges carry pressure thrust, protecting anchors and the rest of the system.

Typical Materials Used:

- Component Common Materials

- Bellows SS 304, SS 316, Inconel, Hastelloy

- Hinges Carbon Steel, SS 304, SS 316

- Pins/Bolts High-strength steel (hardened/tempered)

- End Fittings Same as pipeline (CS or SS)

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email